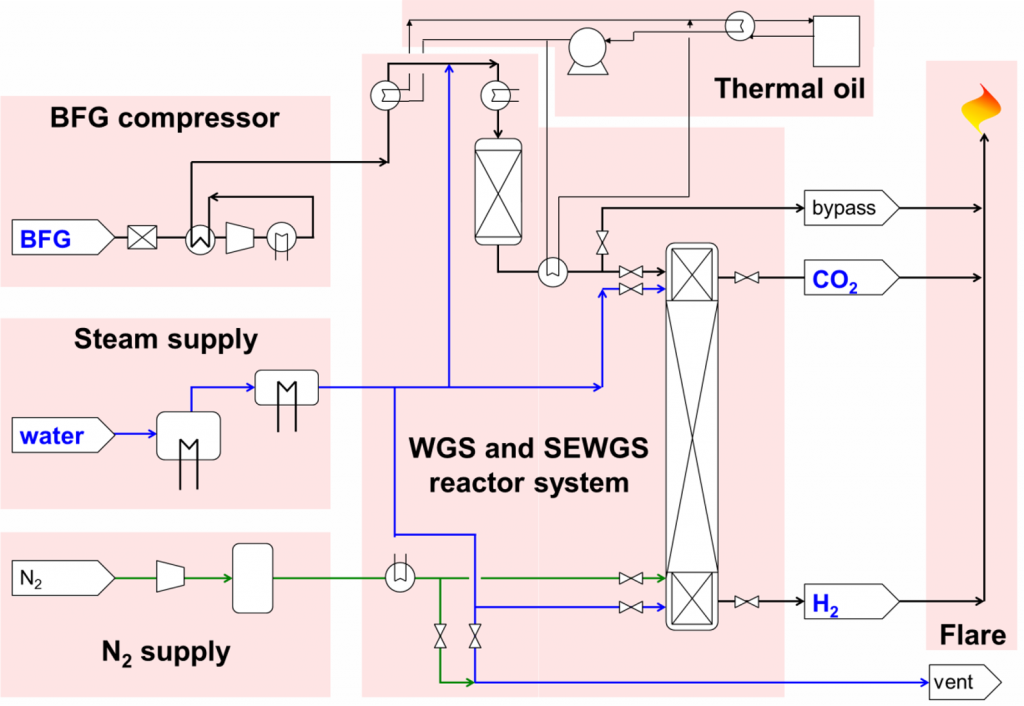

In the STEPWISE project, the SEWGS process is demonstrated at an equivalent capture rate of 14 tCO2/day. The pilot unit is designed, build and operated by a Swerim – ECN.TNO collaboration. It is situated at the Swerea Mefos facilities in Luleå, Sweden. The pilot is fed with a feed of 800 Nm3/h Blast Furnace Gas from the adjacent steel plant of SSAB. In 2015, a 500m long tie-in line has been constructed delivering untreated BFG to the Pilot. The pilot unit consists of a BFG compression section, an advanced WGS section and a SEWGS section.

Advanced WGS section

In conventional CO2 removal technologies, the CO conversion to CO2 within the WGS section dictates the capture ratio of the downstream separation. High CO conversion is required to reach a high CO2 capture ratio, at the expense of a significant steam addition to the WGS section. On the contrary, in the SEWGS process the CO conversion occurs in both the WGS as the SEWGS section and the CO conversion of the WGS section can be relaxed. This yields a potential steam savings and allows the use of novel catalysts and process schemes. Typically, the WGS section is operated at steam/CO feed ratios of 1.5 to 2.0 mol/mol.

SEWGS section

SEWGS is multi-column reactive hot-PSA process. In the pilot, however, a single column will be used to demonstrate the H2-CO2 separation. The single column contains about 2.5 ton of sorbent material and is operated in counter-current pressure-swing mode. Operation of the pilot will focus on the steam requirement to obtain the targeted separation efficiency, cycle design, heat management and the interplay between the WGS and the SEWGS sections. The data serves as reference to fine-tune the SEWGS simulation model. Material durability demonstration using real BFG during the two test campaigns will prove the unique functionality of this benign adsorbent.

The schematic below represents the lay-out of the pilot plant. BFG is compressed, pre-heated and steam is added before it enters the WGS reactor. The shifted BFG then enters the single column SEWGS reactor, where the feed is separated into a H2-rich and CO2-rich product.